Beryllium Copper Alloy

Beryllium copper is a kind of alloy that consists of Be and Cu, which has excellent performance in elasticity, strength and wear or corrosion resistance.

Beryllium Copper Rod

Beryllium copper rod is composed of Be and Cu and has excellent performance in electrical and thermal conductivity.

Beryllium Copper Plate

Beryllium copper plate is composed of Be, Cu and other trace elements and it has many advantages, such as low elastic hysteresis, high fatigue strength and no sparks of impacting.

Beryllium Copper Tube

Beryllium copper tube has better performance than other materials in strength, toughness and elasticity, so it has a broad prospect in the mold, the explosion-proof tools and wears parts.

Beryllium Copper Spring

Due to excellent relaxation resistance, wear resistance and radiation resistance, beryllium copper springs mainly used in EMI (Electromagnetic Interference).

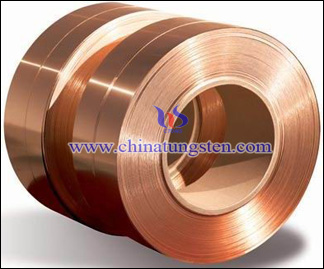

Beryllium Copper Belt

The material of beryllium copper belt can be divided into C17200, C1720, C17000, C17300, C17500, C17510, Qbe2, Qbe1.9, Qbe1.7, Qbe0.6-2.5, Qbe0.4-1.8, Qbe0.3-1.5, Qbe1. 9-0.1 and so on, the common specifications is 0.01-2.0mm in thickness, 305-600mm in width.

Beryllium Copper Reed

Beryllium copper reed can effectively close the porosity between two contact surfaces and provides good EMI shielding effect. Besides, it is able to be electrical plated with diverse metals to ensure the compatibility of the contact surface with heat, which is a kind of ideal materials for EMI shielding.

Beryllium Copper Wire

Beryllium copper wire is also known as supper elastic beryllium copper thread. It has excellent fatigue resistance and elasticity, which becomes the basic material for welding, electronics, instrumentation and other fields.

Beryllium Copper Electrode

Beryllium copper electrode usually used in resistance welding, and after solid solution and aging treatment, its strength and wear resistance can reach the level of alloy steel. However, it has low soften temperature, which will soften at the temperature exceeding 823K. Therefore, it is not suitable for spot welding or seam welding electrodes with small contact area and high surface temperature, whether it will cause severe adhesion due to low thermal and electrical conductivity.

Beryllium Copper Stamping Part

Beryllium copper stamping part is fabricated by beryllium copper plate stamped by presses and molds, which has been widely used in automobile, radiator parts, motors, containers, machinery manufacturing, instruments and other mechanical fields.