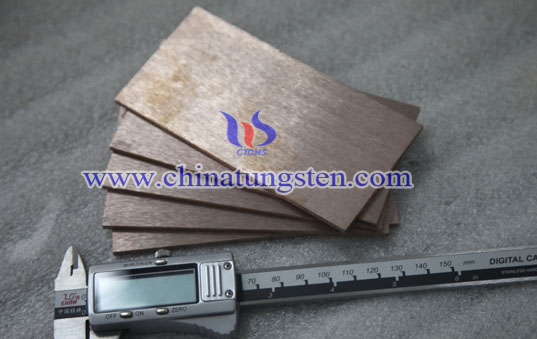

Nano Tungsten Copper Composite Material

Introduction

Nano tungsten copper composite material has conventional crystalline materials do not have a specific energy and materials by domestic and foreign researchers. Currently Nano tungsten copper composite material focused on preparation and properties of nano tungsten copper composite sintered material aspects. Such materials are mainly used in microelectronics packaging materials, high performance electrical contact electrode material as well as aerospace, military and high-temperature areas of tungsten copper composite material. Fully dense, high-performance fine-grained tungsten copper composites prepared are key nanostructure tungsten-copper composite powders acquisition.

Process

At present, many domestic and foreign research syntheses of nano tungsten copper composite material powders by sol - gel method, spray drying, mechanical - thermochemical hair, mechanical alloying and the like.

Densification Factors

Sintered tungsten copper composite powders nano densification factors include three aspects. First, the impact of the molding pressure. The relative density of tungsten-copper composite powder compacts are different copper content increases and the molding pressure increase, when the molding pressure to 350Mpa, compacts relative density increases slowed. Secondly, the influence of sintering temperature and holding time. Since the liquid phase sintering sintered tungsten copper composite material used in the sintering temperature within a certain range of the increase will help improve the diffusion rate of copper particles of tungsten, tungsten copper composite powder to achieve uniform and densification, but the high sintering temperature leads to volatile copper liquid, the material to produce sub-segregation, but will reduce the density, the sintering temperature is the key to determine the choice of the sintering process. In addition, the mechanical alloying process also affects the density. Tungsten solid solution strengthening mechanical alloying of the interaction between tungsten and copper, increasing the chance of contact between tungsten and copper, thereby improving the performance of sintered tungsten-copper composite powders. Tests show that mechanical alloying process in many ways to improve the performance of sintered tungsten copper composite powders is one of the best preparations to get close to the full density tungsten copper composite material. Finally, hot pressing to obtain a higher degree of densification of the tungsten-copper composite material at a lower temperature.