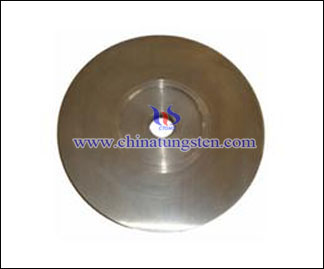

Tungsten Copper Disc

Introduction

Tungsten copper disc is made by copper tungsten (WCu) material. Tungsten copper disc is subjected to extreme mechanical and thermal stresses during operation. For fractions of a second, temperatures rise to several thousand degrees as a result of the arcing. Our tungsten copper alloy disc materials are used because of tungsten copper alloy electrode unique physical properties. Tungsten copper alloy disc material offered by us is high quality. We can provide all kinds of tungsten copper disc as your requirements. Tungsten copper electrode is easy to be machined.

Features

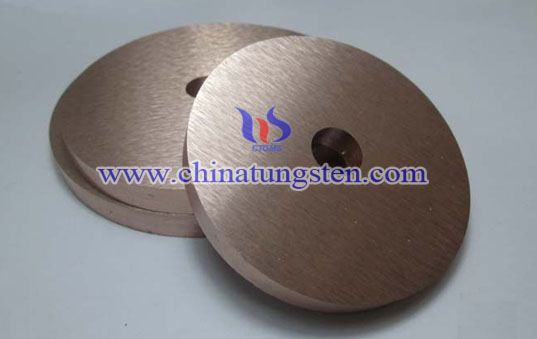

Tungsten copper disc with the advantages of plasticity, high conductivity copper tungsten excellent high purity tungsten powder metal features and high-purity copper powder by isostatic pressing, high temperature sintering, melting infiltration composite copper refining process. Broken arc performance, good electrical and thermal conductivity, low thermal expansion, high temperature does not soften, high-strength, high-density, high hardness.

Properties

Low expansion characteristics of tungsten, and having high thermal conductivity characteristics of copper, its thermal expansion coefficient and the electrical and thermal conductivity can be changed to adjust the composition of the material and thus provides a convenient to use of the material.

Combines the advantages of tungsten and copper, high temperature, arc erosion resistance, high strength, than the major, good electrical conductivity, thermal conductivity, ease of cutting and sweating Ling but other characteristics, due to the high hardness of tungsten, high melting point, The anti-adhesion characteristics, often used to make a certain wear resistance, high temperature resistance projection welding, butt welding electrode.

Application

Tungsten copper disc is widely used for tungsten steel, high-temperature super-hard alloy die to electrical erosion is required, the common electrode wear big, slow, galvanic corrosion of tungsten copper high speed, low loss rate, the precise shape of the electrode, excellent processing performance can be to ensure the accuracy of the work piece is greatly improved.