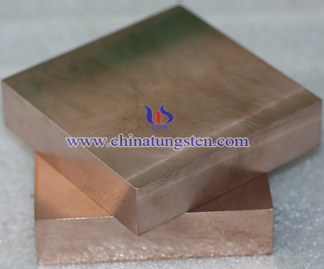

Tungsten Copper Sol Gel Method

introduction

Tungsten copper sol gel method with hydrolysis and polymerization basic reaction, which are in preparation of high purity at a low temperature, evenly distributed, high chemical activity of single and multi-component mixtures. It is a metal alkoxide and its compounds as raw materials, under certain conditions hydrolysis medium and catalyst - the polycondensation reaction solution into a gel, and then by drying and heat treatment method of obtaining synthetic materials.

En traitement

Compared with conventional sintering method, sol gel method products with high uniformity and high purity, the temperature is 400℃~500℃ lower than conventional sintering method, the reaction process is easy to control, can greatly reduce the side effects of the new phase formed. At the same time, this kind of method solve the mechanical mixing powder prepared tungsten copper composite powder particle size is too large, mechanical impurities, tungsten copper mixing uneven and other issues. Mainly include the followings.

1. Nano powder sample single structure, good chemical homogeneity.

2. High purity samples.

3. Heat treatment temperature of the sample required is relatively low.

4. Relatively small sample particles

Disadvantages

The method used by the higher cost of raw materials, the processing time is longer, the product easy to crack, when the sintered article may remain imperfect pores and OH- or C, and the process is complex, there is a greater difficulty in mass production.