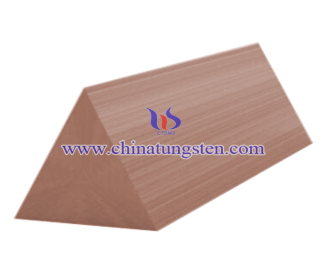

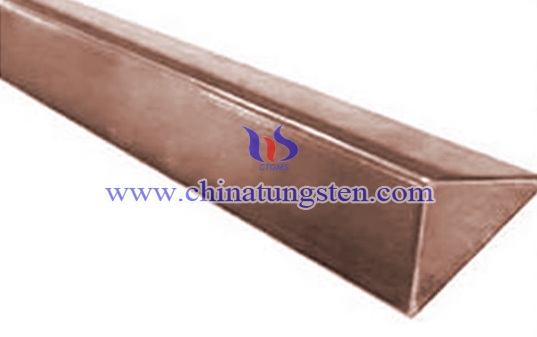

Tungsten Copper Triangle Electrode

Introduction

Tungsten copper products, a staple of the refractory metals industry, are meeting the growing demands of high-tech applications such as major electronic equipment, safety equipment, weighted gaskets, EDM electrodes in spark erosion cutting equipments, heat sinks, arc contacts and vacuum contacts, and other electrical and electrical/thermal applications.

Tungsten copper triangle electrode, as its name indicates, is a bar in triangle shape. Unlike regular blocks, sheets or rods, triangle bars are rare and only custom-made for specific needs.

Advantages

Tungsten copper triangle electrodes have the characteristics of low thermal expansion, good thermal conductivity and electrical conductivity, excellent arc resistance, excellent wear resistance and high temperature strength of copper-tungsten alloy metal composite materials, and can withstand extreme temperatures and harsh environments.

Production Process

Tungsten copper alloy adopts advanced vacuum infiltration process, and are strictly fulfilled the national GB/T8320-2017, international GB/TN320-2003 and ASTM B702 tungsten copper standards. The corresponding grades are WCu7, WCu10, WCu15, WCu20, WCu30, WCu40, WCu50, WCu7, 5W3, 10W3, 20W3, Class10, Class11, Class12; other grades can also be customized.