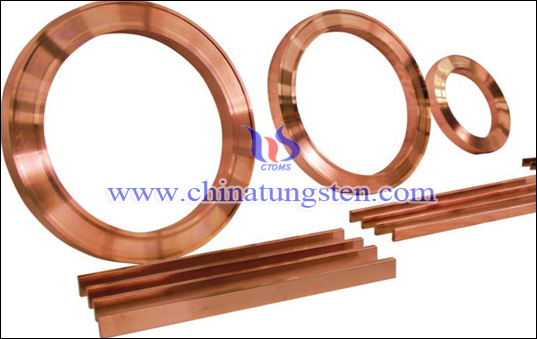

Chromium Zirconium Copper End Ring

Introduction

Chromium zirconium copper end ring is also called short-circuit ring, is an important welding structure in asynchronous traction motor and the main role is to carry an electric load, high speed running and frequent braking.

Process

Asynchronous traction motor rotor consists of the shaft, pressure ring, rotor plate, knifes and end ring (short-circuit ring) and so on. In the process of end ring welding, it uses vertical welding or medium frequency inducted brazing, that is aligned with the first end ring placed on the course of the induction coil and isolates the end ring and the induction coil mica plate; then bars embedded in the rotor core is placed on the side of the ring, and preset the solder and flux, one-step heated complete end to end all the welding electrodes rotor ring and a guide bar. After welding, it needs hot water and a brush to completely remove flux residues and residues.

Failure Analysis

Chromium zirconium copper end ring main cause of failure during the motor operation: 1. High liquid metal brittleness, leads to end ring cracks early; 2. The part of motor rotor higher than the surface of rotor core; 3. Withstand the instantaneous high temperature, end ring has been penetrated and the strength decreased; 4. End ring pulled off by the friction during the motor rotating and form the breach in electric etching.