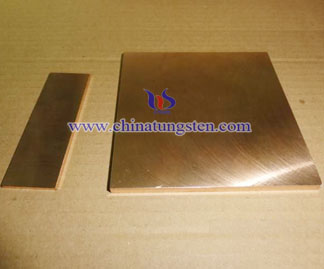

Chromium Zirconium Copper Plate

Introduction

Due to good electrical and thermal conductivity, chromium zirconium copper plate is suitable for machinery manufacturing, such as die block, switch, contacts and auxiliary devices.

Characteristics

The physical indicators of chromium zirconium copper plate: Hardness > 75 HRB; after 550 ℃ to maintain 2h, quenched with water cooling compared to the original hardness of not less than 15%; eddy current conductivity meter conductivity measured by the average of three points ≥44MS / M. After aging treatment, the hardness, the strength, the electrical and thermal conductivity can be further improved and more suitable for welding process.

Application

Mold base material: chromium zirconium copper has already begun in the mold industry as a general instead of beryllium copper mold material. Such as shoe mold, plumbing, mold, general requirements for smooth high plastic mold, and other connectors, guide wire, and other high strength wire products. Features Applications: chromium zirconium copper has good electrical conductivity, thermal conductivity, high hardness, wear antiknock, crack resistance and high softening temperature, welding speed, low cost, suitable for use as EDM and welding electrodes, is the priority based on the costs to replace tungsten-copper material.