Tungsten Copper Hot Hydrostatic Extrusion

Introduction

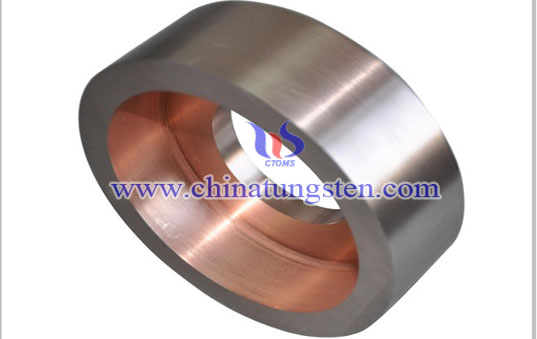

Tungsten copper material is composed of tungsten and copper, which contains all advantages of this two metals, such as high strength, high hardness, excellent wear and corrosion resistance, good resistance to arc erosion, welding resistance, excellent electrical and thermal conductivity, which can be widely used in high-voltage switch, vacuum switch, electrical contacts, EDM electrodes, welding electrode and plasma plating electrodes fields. Tungsten copper hot hydrostatic extrusion is a kind of new manufacturing process based on powder metallurgy technology.

Processing

Hot hydrostatic extrusion is working on a four-post hydraulic machine, mold using three sets of combination of pre-stressed die, while using the outer heating coil and ceramic heating tube mold preheated.

Advantages

With the increasing sintering temperature, the relative density of sintered compact increases, trace activator Ni added help to improve the relative density of sintered compact. Temperature increase can improve the wettability of copper solution to solid tungsten, and it is beneficial for Cu solution spreading on the surface of W grain, reducing the resistance of rearrangement process and improves the densification rate. Furthermore, with the increasing temperature, the viscosity of copper solution decrease, this is beneficial for improving the flowing rate by the capillary force and contributing the densification process.