Tungsten Copper Hot Pressing Sintered

Introduction

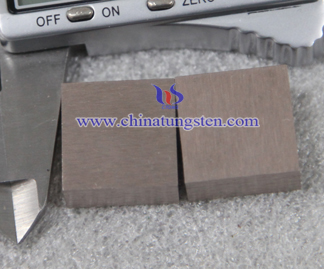

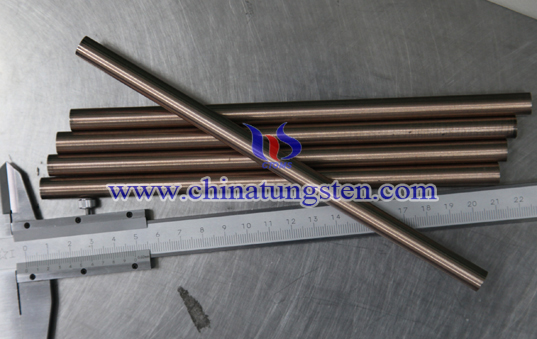

Tungsten copper hot pressing sintered process of cold pressing method blank - vacuum sintering - canned hot extrusion. Because tungsten copper composite material has excellent electrical and mechanical properties, as electrical contacts, the discharge electrodes and electronic packaging materials are widely used in electrical and electronic fields. In order to expand its product range and applications need to further improve the density and mechanical properties of the material.

Steps

The main steps of tungsten copper hot pressing sintered method is: firstly, tungsten copper powder mixed with flour, then into the model, the heating process pressure is applied from a uniaxial direction, so that molding and sintering simultaneously. This method of preparation of tungsten-copper material can significantly reduce the sintering temperature, grain growth can be suppressed, since the addition of copper during sintering tungsten powder in a thermoplastic state, contribute W, Cu interface contact diffusion, flow and mass transfer process carried out thereby obtaining a high density under less pressure, so hot pressing method can obtain fine grain size, high density, good thermal conductivity properties of tungsten copper products. The disadvantage pressing sintering material is sintered tungsten-copper complex equipment, the process is difficult, you need to protect or hydrogen vacuum sintering, mold requires high energy consumption, low unit production efficiency, high cost of production is not commonly used.

Conclusion

With the increase of sintering temperature, tungsten, copper density gradient material layers increases, tungsten, copper W / Cu20 hardness of sintered samples after sintering increases as the temperature increases to remain unchanged, W / Cu33 and W / Cu50 of hardness increased at first and then decreased. With the increase of holding time, shrinkage of the sintered body increases, a reasonable holding time of 2 ~ 3h.

In the sintering temperature 1060 ℃, pressure 85MPa, holding time 3h under process conditions, the use of particle size and the ratio of hot solid phase sintering method can be prepared by full density gradient of the W-Cu heat sink material, each graded layer and thermal boundary layer the relative density was 98.6%, 99.1% and 99.5%, respectively 91.6,95.6 and hardness 74.4HRB.