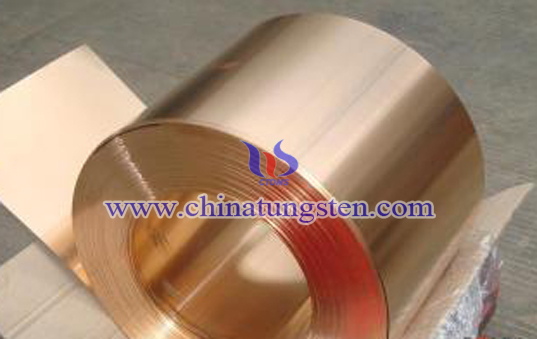

Beryllium Copper Belt

Introduction

The material of beryllium copper belt can be divided into C17200, C1720, C17000, C17300, C17500, C17510, Qbe2, Qbe1.9, Qbe1.7, Qbe0.6-2.5, Qbe0.4-1.8, Qbe0.3-1.5, Qbe1. 9-0.1 and so on, the common specifications is 0.01-2.0mm in thickness, 305-600mm in width.

Characteristics

After solution and aging treatment with high strength, hardness, elastic limit and fatigue limit, elastic hysteresis, and having corrosion resistance and processing properties, beryllium copper alloy is irreplaceable material for submarine cable repeater structure. Based on wear resistance, low temperature, non-magnetic, high electrical conductivity, no sparks, it also has good mobility and ability to reproduce fine patterns.

Notice

It is easy to form beryllium oxide (BeO) in the process of smelting, casting, heat treatment, welding, cutting and other high-temperature processing operations. And most of the BeO be firmly attached to the surface of the workpiece, a few small particles (<10μm) will be suspended in the air, leading to inhalation of staff. So it is necessary to have complete orientation exhaust plants in manufacturing, cutting and polishing process should be processed in wetted by cooling liquid. The content of Be should not exceed 2 μg/m2.