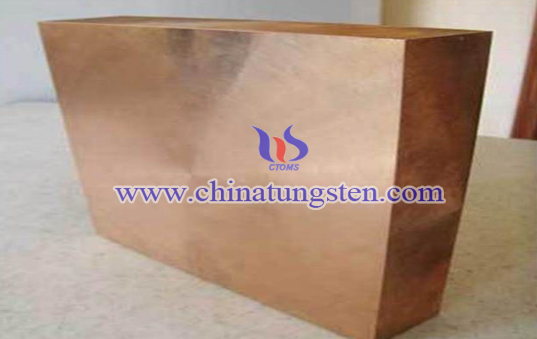

Beryllium Copper Plate

Introduction

Beryllium copper plate is composed of Be, Cu and other trace elements and it has many advantages, such as low elastic hysteresis, high fatigue strength and no sparks of impacting.

Characteristic

Beryllium copper plate has excellent performance in mechanical, physical and chemical properties, and its cold and heat resistance, electrical conductivity, and fatigue resistance can be further improved after quenching. In addition, it shows excellent corrosion resistance in air, freshwater and seawater. The corrosion of beryllium copper alloy speed in seawater: (1.1-1.4) × 10-2mm / year; corrosion depth: (10.9-13.8) × 10-3mm / year. After etching, the strength, elongation rate did not change, so it can be maintained in seawater for more than 40 years, which is submarine cable repeater structure irreplaceable material. In sulfuric acid: sulfuric acid in a concentration of less than 80% (at room temperature) corrosion depth 0.0012-0.1175mm, concentrations greater than 80% is slightly accelerate corrosion.

Application

It can be widely used in manufacturing various types of mold inserts, replace steel in mold manufacturing with high precision and complex shape and welding electrode. It also plays an important role in inserts pieces of plastic injection molding mold, mold core, die-casting punch, hot runner cooling system, thermal conductivity mouth, blow the whole cavity mold, automotive mold, wear plates, micro-motor brush, cell phone, batteries, which is the indispensable industrial material in national economy.