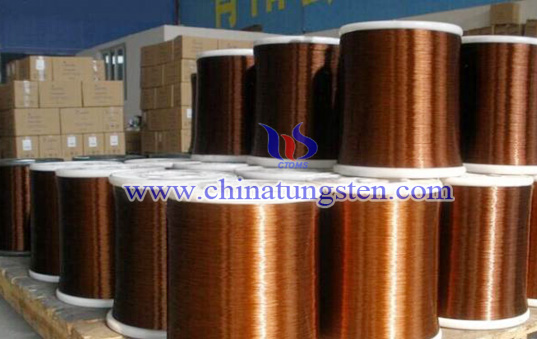

Beryllium Copper Wire

Introduction

Beryllium copper wire is also known as supper elastic beryllium copper thread. It has excellent fatigue resistance and elasticity, which becomes the basic material for welding, electronics, instrumentation and other fields.

Process

1) Tension: The soft state of the wire and the semi - finished wire rod through the quenching process has been eliminated; 2) Quenching: the optimum quenching temperature 780-790℃, heat preservation time is not more than 15 minutes, released quickly into the water tank for cooling and air compression of material attached to dry; 3) Aging treatment: after the cold processed with a certain degree of hardness of the finished product at 320℃ under the aging treatment 60min; 4) Pickling: after quenching, the surface oxide layer is mainly CuO and BeO, using 10% of the HNO3 and 15%H2SO4 mixed solution to pickling at 40-60℃ about 3-6min, and the time should not be too long; 5) Welding: in order to improve the production efficiency and achieve long - term stretch, it can be relatively short semi-finished material for welding.

Grades

ISO |

China GB |

USA ASTM |

Japan JIS |

Germany DIN |

Britain BS |

France NF |

QBe2 |

CuBe2 |

C17200 |

C1720 |

CuBe2 |

CB101 |

CuBe1.9 |

QBe1.9 |

CuBe2 |

- |

- |

CuBe2 |

CB101 |

CuBe1.9 |

QBe1.9-0.1 |

CuBe2 |

C17200 |

C1720 |

CuBe2 |

CB101 |

CuBe1.9 |

QBe1.7 |

CuBe1.7 |

C17000 |

- |

- |

CB101 |

CuBe1.7 |

QBe0.6-2.5 |

CuCo2Be |

C17500 |

- |

- |

- |

- |

QBe0.4-1.8 |

CuNi2Be |

C17510 |

- |

- |

- |

- |

QBe0.3-1.5 |

- |

- |

- |

- |

- |

- |