Tungsten Copper Composite Rivet Contacts

Introduction

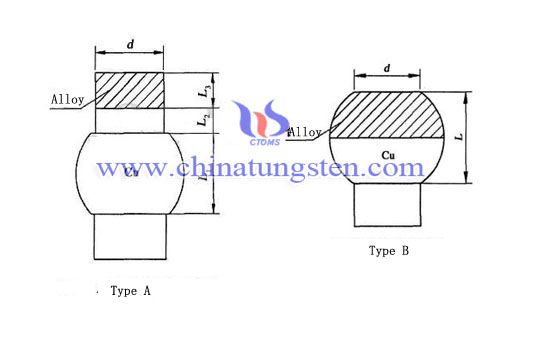

Composite rivet contacts combine by two or more than two material. Currently most of the rivet contacts are adopted production method of cold welding principles, which is put two materials upsetting together. It will have dramatic distortion on the composite interface and then composite together.

Through analysis can be found, rivet contacts forming's wire diameter size is depending on the diameter of foot nail. In this case, if the copper material volume is greater, the length of copper material will also be longer than normal, which will also be able to obtain sufficient deformation length. But the head diameter of contact is the main factor for the volume of head's copper material, it has become the head of the main factors affecting the distribution of stratified, so contacts head diameter and the ratio between the diameter of the foot have a greater impact on the multi-layer distribution.

Years of production experience has shown that the ratio of the diameter of the contact head and foot diameter of 1.8 to 2.2 is desirable. In this context, upsetting deformation of material sufficiently homogeneous stratified distribution, a good combination of strength and a relatively low single grain tungsten copper alloy consumption.

To ensure the rivet contact having a better appearance, multi-layer distribution and bonding strength, such as quality, refer to the following table data for production rivet contacts.

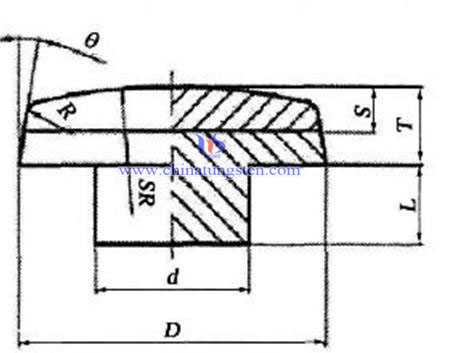

Rivet Contact Structure Design Recommendations

| Structure proportional | Recommendations | Schematic |

| Head Diameter D Vs Foot Diameter d | D/d=1.8~2.2 |  |

| Head Thickness T Vs Foot Length L | T/L=0.4~0.7 | |

| Stratified Thickness S Vs Head Thickness T | S/T=0.35~0.5 | |

| Spherical Contact SR Vs Head Diameter D | SR/D=1.6~3.0 | |

| Draft Angle A | A=0.8°~12° |