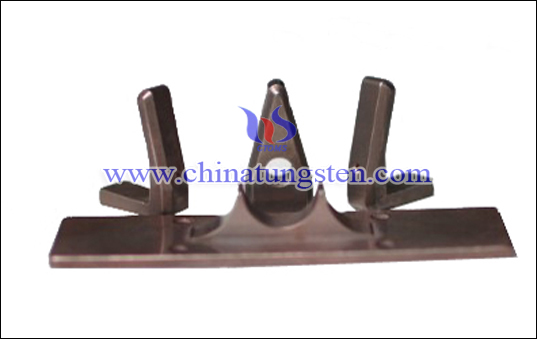

Tungsten Copper Claw Electrode

Introduction

In the low-voltage transmission and distribution systems over-voltage protection, B-class protection focused on building main distribution cabinets, lightning protection device provided in the main distribution cabinet among its main function is 90% of the energy can be tolerated after the first stroke, mainly used in lightning protection devices to protect the gap (SPG), and tungsten-copper alloy electrode material discharge gap as compared to other SPG advantage electrode is stable, precise size, easy to assemble.

Properties

| Grade | Composition (%wt.) | Density(g/cm³)≥ | Hardness(HRB)≥ | Conductivity(%IACS)≥ | Class |

| W50Cu | W50+Cu:Blance | 11.85 | 65 | 54 | |

| W55Cu | W55+Cu:Blance | 12.30 | 70 | 49 | 10 |

| W70Cu | W70+Cu:Blance | 13.85 | 85 | 42 | |

| W75Cu | W75+Cu:Blance | 14.50 | 94 | 38 | 11 |

| W80Cu | W80+Cu:Blance | 15.15 | 98 | 34 | 12 |

| W85Cu | W85+Cu:Blance | 15.90 | 240HB | 30 | |

| W90Cu | W90+Cu:Blance | 16.75 | 260HB | 27 |

Advantages

Tungsten copper electrode is a claw from high purity tungsten powder of high purity and good ductility combined with high conductivity copper by isocratic pressing, high temperature sintering, melting refined craft made of composite metal material. Good electrical conductivity, thermal expansion of small, does not soften under high temperature, high strength, high density, and high hardness.