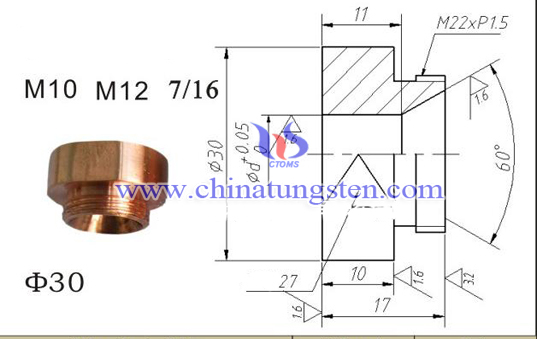

Tungsten Copper Nut Electrode

Introduction

Tungsten copper nut electrode welds bolt and nut together and achieves higher embossing hardness and higher welding strength, which has been widely used in machinery automation and aerospace fields.

Advantages

1. Tungsten copper has high hardness, high strength and excellent performance in electrical and thermal conductivity; 2. Using one-step forming process, no holes in welding seam and has high precision and concentricity; 3. High torsional strength can effectively ensure the quality and precision of processing; 4. Flexible enough for a range of products, can meet the mass-production and has longer service life.

Application

Combined with tungsten copper and chromium zirconium copper seamlessly. On the one hand, the tip uses tungsten copper with highhardness, wear resistance and excellent electrical and thermal conductivity; on the other hand, electrode base is made of chromium zirconium copper with high temperature strength, good oxidation resistance. With the automatic bump welding equipment, it has a broad application prospect in automotive and aerospace fields.