Tungsten Copper Handle Electrode

Introduction

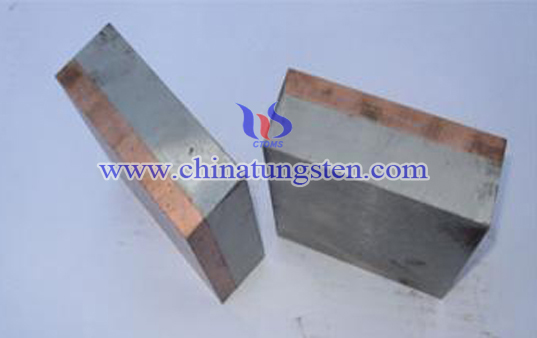

Tungsten copper handle electrode also called tungsten copper composite electrode, one side is tungsten copper, and another side is high tensile steel. Tungsten copper handle electrode uses a unique technology to produce vacuum diffusion welding, surface welding seamless, the overall effect is good, mainly used in EDM electrodes increases efficiency.

Advantages

One benefits of tungsten copper handle electrode is conducive to a magnetic iron fixed on a magnetic base so that the processing time to ensure accuracy. Tungsten copper composite electrode is combined with iron, to prevent the use of conventional welding processes this compound in the presence of pores, cracks problem.

1, Tungsten copper combines with iron, which mechanical properties make it more reasonable and easier to use. Small precision machining electrode deformation problem is a good solution;

2, The electrode can be directly adsorbed on magnetic bench grinding its flatness after processing, surface finish and dimensional accuracy than other processing methods can not reach. Utmost superiority in processing large plane electrodes;

3, The reference electrode after grinding reproducibility is good, especially for multi-step combinations need workers electrode;

4, a plurality of electrodes can be processed simultaneously, can greatly improve work efficiency;

5, The loss of the electrode by grinding can be reused, usage rate, a substantial increase in work efficiency and reduce processing costs.

6, A magnetic iron conducive fixed on the magnetic base so that the processing time to ensure accuracy.

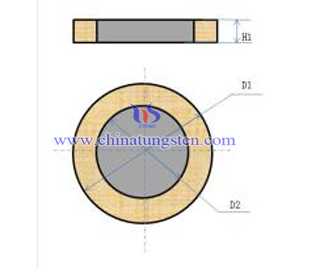

General Specifications

| Whole Length | Steel Shank Length | WCu Length | Thickness | Width |

| 60 | 50 | 10 | 2 | 50 |

| 60 | 50 | 10 | 2 | 100 |

| 60 | 50 | 10 | 4 | 50 |

| 60 | 50 | 10 | 4 | 100 |

| 60 | 50 | 10 | 6 | 100 |

| 60 | 50 | 10 | 8 | 100 |

| 60 | 50 | 10 | 10 | 100 |

| 60 | 50 | 10 | 15 | 100 |

| 60 | 50 | 10 | 20 | 100 |