Tungsten Copper Electrical Contacts

The high Electrical & thermal conductivity of copper are combined with the arc-resistant & non-welding properties of tungsten or their carbides to form an extensive series of compositions each designed to give the best performance for your particular application. These materials are used for such heavy duty contact applications as:

- Circuit breakers, air; oil immersed

- Arcing tips or arc runners

- Make break contacts

- Heavy duty conductors, relays; switches.

Product Standard: GB/T 8320-2003

The high electrical and thermal conductivity of tungsten copper alloy allows a cool, effective transfer of power, while the excellent arc-resistance properties of tungsten copper minimize arc erosion and transfer problems. These characteristics can be varied by composition more silver or copper yields higher electrical and thermal conductivity, while a higher refractory metal content results in superior arc erosion properties. We offer a variety of composites to meet your demands. Regardless of the environment (oil-filled devices, air and gas circuit breakers, contactors, high voltage switch gear) or the application (arcing contacts and plates, arc runners, current carrying members and blade facings), you won't be disappointed in electrical contacts made from our copper tungsten composites.

grade |

Composition |

Density |

Hardness |

Electrical Conductivity |

Application |

CuW 60 |

60%W |

13.0 |

145 HV |

52% IACS |

Arcing Contact |

CuW 70 |

70% W |

14.2 |

197 HV |

46% IACS |

Arcing Contact Vacuum Switch |

CuW 72 |

72% W |

14.5 |

200 HV |

40% IACS |

Spark Erosion & Electro Chemical Machining |

CuW 75 |

75% W |

14.8 |

220 HV |

44% IACS |

Arcing Contact |

CuW 75 |

75%W |

15.2 |

240 HV |

40% IACS |

Projection Welding |

CuW 78 |

78% W |

15.2 |

230 HV |

40% IACS |

Arc Contact resistance welding |

CuW 80 |

80% W |

15.5 |

235 HV |

40% IACS |

Arcing Contact |

CuWC 67 |

67% WC |

12.7 |

350 HV |

32% IACS |

Electrical Upsetting |

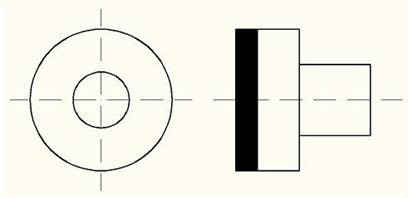

We will analyze your application & recommend sintered materials to suit your requirements. We can often suggest design revisions that may improve the performance of the product & reduce your costs.From simple to complex geometry, Chinatungsten produces custom electrical contacts that meet the demands of customer applications. A variety of shapes and sizes for contact requirements are possible because of powder metal technology.

We will analyze your application & recommend sintered materials to suit your requirements. We can often suggest design revisions that may improve the performance of the product & reduce your costs.From simple to complex geometry, Chinatungsten produces custom electrical contacts that meet the demands of customer applications. A variety of shapes and sizes for contact requirements are possible because of powder metal technology.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595

More Info: Tungsten Copper Tungsten Copper Alloy