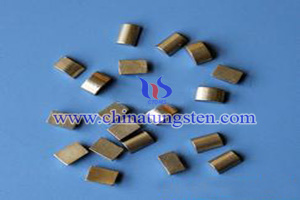

Tungsten Copper Embedded Block

Introduction

Tungsten copper embedded block is manufactured by powder metallurgy, which is a kind of typical sweating material. Even if at high temperature (3000℃), the copper evaporation will take away the most part of heat and effectively reduce the surface temperature and keep the strength. In addition, it has perfect conductivity and plasticity, which is beneficial for improving the mechanical properties of the embedded part.

Type

1. Electrical materials: In electrical contact and electrical processing, such as electrical contacts, point contacts, electrodes, welding, riveting, electric upsetting, etc., its good conductivity and anti-arc ablation to ensure the accuracy of processing; 2. Instantaneous high temperature materials: Embedded in some vulnerable to high temperature ablation, particle erosion of the site, effectively improve its anti-ablation and thermal shock resistance; 3. Guide materials: Mainly used for a variety of wire rolling, plays an important role in guiding and protecting the workpiece.

Application

Tungsten copper embedded block not only has high melting point (3410℃), low CTE (Coefficient of Thermal Expansion) of W, but also has high conductivity of Cu. So it can control the performance by adjusting the material content. It has been widely used in high pressure, ultra-hydraulic switch and circuit breaker contacts, protection ring, for the electric pier rough anvil material, automatic submerged arc welding nozzle, plasma cutting machine nozzles, welding machine, welding machine welding head, sealing gas electrode and spark electrode, spot welding, touch welding materials.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595