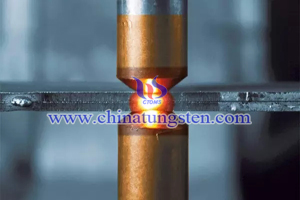

Tungsten Copper Resistance Welding Rod

Introduction

Tungsten copper resistance welding rod has excellent thermal and electrical conductivity, which uses the resistance heat current run through the contact area and near to turn into melting or plastic state and combine the metals. It plays an important role in pushing the welded component with high pressure, providing a large amount of welding current on the part of welding and promoting the cooling process on the welded component.

Type

According to the methods of welding, tungsten copper resistance welding rod can be specifically divided into spot welding rod, seam welding rod, projection welding rod, butt welding rod. 1. Spot welding rod: The weldment assembled into lap joint, and pressed between two cylindrical electrodes, the use of hot-melt resistance of the base metal to form a solder joint resistance welding method used for welding sheet metal; 2. Seam welding rod: It is similar to spot welding process, except that uses disc-shaped roller electrode instead of cylindrical electrode. The weldment assembly into a lap or butt joints, and placed between two electrode rollers, roller pressing and weldment rotation, continuous or intermittent power transmission, forming a continuous weld seam, which is mainly used for more regular and sealing high performance requirements of the structure; 3. Butt welding rod: The weldment welded along the entire contact surface; 4. Projection welding rod: A variant form of spot welding; on a workpiece has preformed bumps, when the projection welding, one can form one or more of the nugget at the joint.

Advantage

1. Nugget formed, is always surrounded by a plastic ring, molten metal and air separation, metallurgy process is simple; 2. Heating time is short, heat concentration, it is a small heat-affected zone, deformation and stress is also small, usually do not have to arrange correction after welding and heat treatment process; 3. It does not need welding wire, rod and other metal stuff or oxygen, acetylene, hydrogen, so the welding costs if relatively low; 4. High efficiency, no pollution and is suitable for mass production.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595