Nano AlN Effect on W-Cu Composite Material Flexural Strength

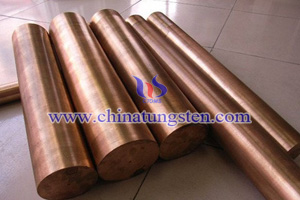

W-Cu composite flexural strength is an indispensable test item, especially for tungsten copper rod. It refers to the resistance to bending without broken, which usually uses three-point or four-point test for evaluation. The standard follows flexural strength (GB / T 6569-86), or ISO 14704-2000 test. Flexural strength test is divided into three-point bending and four-point bending. Each point should be measured 5 times at least (10 in standard) and obtain the average. Flexural strength test conducted on universal testing machine. Used as test strip for the 3 × 4 × 35 (mm * mm * mm). Three-point bending measurement has span of 30mm, loading rate of 0.5mm / min. Three-point bending of the formula R = (3F * L) / (2b * h * h): F- breaking load; L- span; b- width; h- thickness.

When the amount of nano AlN is less than 1%, the flexural strength of tungsten - copper composite does not change clearly, but slightly decreases; while the addition amount is more than 1%, the strength value is greatly decreased. This is mainly due to the decrease in density on the one hand, on the other hand, With the increase of the content of AlN nano particles, the distribution of the reinforcing particles on the grain boundaries of the matrix is too much, which greatly reduces the bonding ratio between the matrix W during sintering, which makes the bonding strength between the particles decrease and the flexural strength decreases.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595