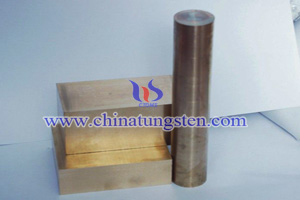

Tungsten Copper Rod Wear Resistance

Introduction

Tungsten copper rod wear resistance is also called as abrasion resistance or durability, which refers to the capability of rubbing against sand paper, and represented by the reciprocal of wear rate (dt / dV or dL / dV).

Type

It is unavoidable that tungsten copper rod wore after using for a long time. There are many wear forms, such as abrasive wear, adhesive wear (glued), fatigue wear (pitting) corrosion. Abrasive wear: caused by external hard particles or hard surfaces in the breeze dual friction surfaces in relative motion the process; Adhesive wear: also known as engaging wear, it refers to the contact surface friction sliding friction occurs local metal adhesion, which destroyed in the subsequent slide relative to the adhesion at the metal crumbs pulled from the surface or parts of the surface scratched; Fatigue wear: friction two pairs of dual surface for rolling, or rolling and sliding compound movement, due to the alternating effect of contact stress, the surface material fatigue fracture formed pitting or spalling, called surface fatigue wear (or contact fatigue wear).

Measurement

Since different friction materials and test conditions, it can be represented by wear index or the consumption of abrasion tester (g/cm2) or its reciprocal. In addition, it refers to the resistance of coated layer to mechanical action, which actually embodies the hardness, the adhesion, cohesion of the coated layer. Under the same conditions, the coated layer has better performance in wear resistance than metal materials, because the viscoelastic effect can buffer, absorb and release the energy. Usually use abrasion tester under certain load and specified speed grinding to obtain coating weight loss in grams.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595