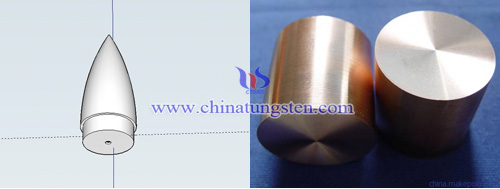

Tungsten Copper Nose Cone

Introduction

Tungsten copper nose cone at the front of a rocket or missile, when it enters the atmosphere at supersonic speed, will have a strong head detached bow shock. It can protect the payload and endure the large temperature difference and high-speed particle erosion at the same time.

Structure

A rocket includes a high thin cylinder, made by sheet metal. The cylinder stores the rocket engine's fuel and refueling tank inside, and rocket propulsion engine is provided at the bottom of the cylinder. In the upper part of the cylinder is fitted with a hollow cone streamlined, connected to the base of the cone cylinder, cone tip upwards. This shape of the cone of the rocket exposed to air cross section of minimum cross-sectional area is reduced to reduce the energy required for rocket discharging air consumption. Generally, the payload of manned spacecraft is placed in the top of the rocket nose cone. It is called as payload fairing cone in space technology, which plays an important role in protecting the payload after rocket ignition and prevent the rocket from destroyed by the enhanced wind of rocket accelerating.

Mechanism

The ablation mainly includes thermal chemical ablation and mechanical erosion. Ablative heat characteristic is the use of short, tungsten, copper nose cone is a typical heat sink material, which is adjusted by the material properties of its own, is evaporated and turned away most of the copper in the heat, so it can keep the allowed temperature inside the craft. In addition, the ablation mechanism can be divided into sublimation, melting and charring, which has a cross-phase relationship of the triple point, at high temperature and pressure, carbon homogeneous melting and evaporation occurs interaction phenomenon exceeds the triple point.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595