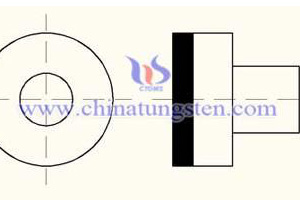

Tungsten Copper Military Contact

Introduction

Tungsten copper military contact has excellent arc ablation resistance and welding resistance, and it plays an important role in military high-load, high-temperature, high –pressure breaker, segment contacts and conductors.

Property

Tungsten copper military contact is the core component of high voltage circuit breaker, isolating switch. Especially the quality of the contact has a direct impact on the quality and the service life of military high-voltage equipment. Tungsten copper contacts has excellent resistance to arc burning and welding resistance, arc breaking performance, good thermal conductivity, thermal expansion of small, does not soften at high temperature, high strength, high density, high hardness. Above 3000 ℃, the copper is liquefied evaporated absorbs heat, reduces the surface temperature of the material. Thus, tungsten copper contact is the best choice for military high-pressure arc.

Process

Generally, it is combined mixed powder sintering with infiltration. But with the development of military-related technology, the performance requirements of the contact material have become stricter. Contact materials will not only have a higher welding resistance, but also need to have a sufficiently high arc resistance compressive strength, low off current as much as possible and very low gas content. Conventional preparation tungsten copper material has low material utilization and the performance is difficult to meet the requirements of military applications. Therefore, in order to achieve military contact material performance requirements and extend the life of using, appears many advanced production technology, such as fiber-reinforced method, isostatic pressing-dipping, rolling sintering process, ion implantation, arc melting method and so on.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595