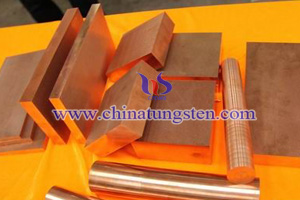

Tungsten Copper - SHS

Introduction

Tungsten copper SHS (Self-propagation High-temperature Synthesis) is also called as combustion synthesis, which uses self-heating and self-conducting effects of the high chemical reaction heat between the reactants to synthesize the material. Once the reactant ignited, it will automatically have not yet respond to the spread of the region until the reaction complete. So it is a kind of new method for manufacturing inorganic compound high temperature materials and FGM (Functionally Graded Materials)

Characteristic

The combustion of the reaction or combustion wave propagation speed (0.1 ~ 20.0cm / s, up to 25.0cm / s), combustion wave temperature or reaction temperature (usually in 2100 ~ 3500K above, up to 5000K). SHS is self-propagating to realize the reaction between powders. Compared with the traditional process of preparing materials, the process is reduced, the process is short and the process is simple. After the ignition, the SHS does not need to supply any energy. As the combustion wave through the sample generated by high temperature can remove the volatile impurities, the product purity improved. At the same time, the combustion process has a larger thermal gradient and faster condensation rate, which is possible to form a complex phase, easy to change from some raw materials directly to another product.

Type

Tungsten copper SHS sintering can be in process by 3 ways as follow: 1. Direct combustion synthesis in the air; 2. The pre-heat treated tungsten copper mixed powder is put into a vacuum reactor for synthesis; 3. The synthesis was carried out in a high-pressure reaction vessel filled with reaction gas. In addition, in order to improve the density of tungsten copper material further, it develop various technology combine SHS with densification, such as SHS densification and SHS welding.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595