Tungsten Copper FGM Spray Deposition

Introduction

Tungsten copper FGM spray deposition is also called as spray forming, which a kind of advanced forming technology develop in nearly 30 years and uses rapid solidification to prepare metal blanks or semi - finished products directly. It consists of molten metal gas atomization, atomization droplet deposition and other continuous process.

Type

Spray rolling: Spray deposition forms a continuous strip product followed by hot rolling or cold rolling; Spray forging: The aim is to produce a hot-forged injection-molded blank, or to extrude the blanks after spray forging; Centrifugal spray deposition: The molten metal is atomized by centrifugation, deposited on a cold substrate, removed from the substrate by the formation of large pipes; Spray coating: The coating is bonded to the substrate and peen at the same time can manufacture fully dense, thermal processed and unstressed deposits. Tungsten copper FGM spray deposition is suitable for manufacturing large thin-walled parts and access to continuous strip, which has fine-grain, excellent properties, save energy and low costs.

Principle

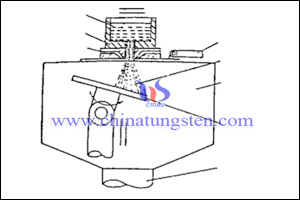

The principle of tungsten copper FGM spray deposition: The molten metal flows out through the draft tube and is broken by the high-speed airflow at the outlet of the atomizing nozzle, and is atomized into a small dispersed droplet jet; atomized droplet jets are accelerated by the momentum of the high velocity gas flow and are strongly exchanged with the gas stream; before reaching the deposition surface, droplets less than a critical size solidify into solid particles, the larger size is still liquid, and the intermediate size droplets are semi-solidified particles containing a proportion of the liquid phase; these large and small droplets of different solidification degree impinge on the deposition surface at high speed and deposit, spread, accumulate and fuse together on the deposition surface to form a thin semi-liquid layer, and then solidify and crystallize, and gradually deposit and grow into a large compact metal solid deposit. In a word, it is composed of two steps, one is atomize the alloy liquid into fine droplets by spraying, and they partially solidified after flying; the other is deposits on the base before completely solidified and further cooling for rapid solidification.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595