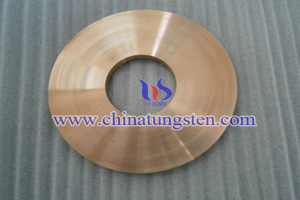

Tungsten Copper FGM Dry Spraying + Gradient Sintering

Tungsten copper FGM dry spraying + gradient sintering main process: mixing ratio of tungsten and copper mixed powder into the ion gas chamber, the use of high-frequency jet to make the raw material powder into ultra-fine particles and cooling; and then the resultant coating is put together with the matrix into a self-made special sintering furnace, and the sintering process is carried out using the temperature gradient. In order to control the shrinkage difference between matrix and coating during sintering process, it is necessary to add a trace element in the preparation process to control the contraction of the two to reach the same. The ultrafine particles in the process can reduce the sintering temperature of the products, the gradient coating crystal is fine so that the coating performance greatly improved, but the experimental process is more complex.

Dry-type spray chamber is mainly composed of dynamic and static pressure chamber, spraying work room, separation chamber and exhaust system. The common method is plasma spraying, which can obtain alloy-based composite gradient lubrication coating without water. The graded structure makes the adhesion of the coating and the substrate significantly improved. Electro-deposition method belongs to wet-type, it has many advantages: 1. without high temperature, high voltage, high vacuum, simple operation; 2. current as the reducing agent process conditions easy to control, easy to adjust the gradient requirements; the coating composition and structure can be effectively controlled.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595