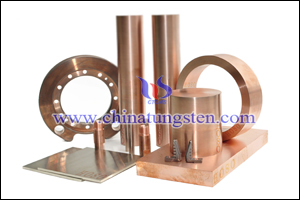

Nano AlN Effect on W-Cu Composite Material Fracture Morphology

Fracture surface morphology can be divided into two types of macroscopic and microscopic morphology, the former can be observed by low magnification microscope, the latter generally need to use scanning electron microscopy. The ductile fracture, brittle rupture, fatigue fracture, stress corrosion cracking or hydrogen embrittlement fracture and other types of fracture all have specific fracture morphology, which can reveal the cause, process and mechanism of materials. The macroscopic observation can be used to determine the nature of the fracture, the initial position and the crack propagation path. Microscopic observation can be used to study the fracture near the starting point, and analyze the fracture mechanism and fracture mechanism.

From the fracture morphology of W-Cu / AlN, the density of the sintered body is high, and there is no obvious pore in the interior; the grain size of the composites was uniform and the size of the particles was smaller than that of the tungsten - copper composite, which was in accordance with the surface morphology of the sintered body; In addition, it can be confirmed that the addition of AlN tungsten-copper composite fracture surface is more smooth, which further confirmed that the addition of AlN on the one hand refinement of the grain structure, on the other hand also led to the toughness of tungsten copper composite decline.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595