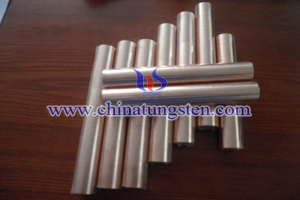

Tungsten Copper Polished Rod

Introduction

Theoretically, tungsten is the best metal electrode material, it has high hardness, high density and high strength, the melting point reaches 3400℃ so that tungsten electrode has low wastage of electrode. However, there are two unavoidable difficulties of pure tungsten: 1. Hard to machining because the high hardness; 2. Cost too much. Therefore, tungsten copper takes advantage of the good properties of tungsten (W) and copper (Cu), which is an ideal electrode material.

Characteristic

Compared with common blank rod, it has better performance in roughness and surface quality. And common copper electrode has large consumption, low precision and efficiency when processing tungsten carbide, high carbon steel, hardened tool steel, while tungsten copper has greatly improved the efficiency and accuracy. Tungsten copper not only has good electrical conductivity, high soften temperature, wear and corrosion resistance, long service life and low frequency of electrode correction, but also save the production costs based on improving efficiency.

Application

The applications of tungsten copper polished rod are diverse include electrode for resistance welding, electrical discharge machining (EDM), high pressure discharge tube, even some military fields (instant high temperature material for piercing, missile insert and rocket ignitor).

Specifications (mm)

D2×200 |

D3×200 |

D4×200 |

D5×200 |

D6×200 |

D7×200 |

D8×200 |

D9×200 |

D10×200 |

D12×200 |

D14×200 |

D15×200 |

D16×200 |

D18×200 |

D20×200 |

D21×200 |

D22×200 |

D25×200 |

D30×200 |

D35×200 |

D40×200 |

D45×200 |

D50×200 |

D60×200 |

The standard length of tungsten copper rod we are able to provide is less than 300(0,+5)mm, and the diameter is Ø1±0.5mm, customized sizes and tolerances are also accepted. |

|||||||

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595