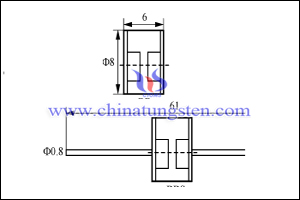

Tungsten Copper Rod for Discharge Tube

Introduction

Discharge tube is a kind component that used in input for preventing from the high voltage. When it is higher than the voltage over its protection standard value, it will be an internal short circuit, and absorbed input high pressure. Tungsten copper rod for discharge tube uses high purity W and Cu powder by isostatic pressing, high-temperature sintering, infiltration, which has excellent conductivity and arc erosion resistance.

Advantage

Tungsten copper rod used as the electrode of high voltage discharge, the temperature of contact material will increase to thousands degrees Celsius in a very short time, which provides the essentials for discharge tube working steady. In addition, tungsten copper material can guarantee the hermeticity between shell sealed and discharge gap, which is suitable for various gas and changing pressure.

Type

According to the content, discharge tube can be divided into gas discharge tube and semiconductor discharge tube. Gas discharge tube: it main consists of inert gas sealed and sintered by metal wire. The working principle is: when voltage is applied to both ends of the gas discharge tube voltage reaches the gas is ionized, the gas discharge tube of a non-self-sustained discharge transition to self-sustaining discharge, the discharge was low resistance conducting state, you can instantly by a large current, the gas discharge tube after breakdown low voltage can be maintained to less than 30V; Semiconductor discharge tube: it is composed by solid four-layer SCR (Silicon Controlled Rectifier) structure. Discharge starts operation when the surge voltage exceeds the break-over voltage semiconductor discharge VBO, when the discharge tube operates in the fold-back device, the role of the voltage across the discharge tube is maintained at a very low (approximately 20V or less) can maintain its low resistance state, absorb surge and protect the devices.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595