Tungsten Copper Rod Tensile Strength

Introduction

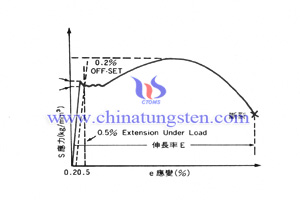

Tungsten copper rod corrosion resistance is the critical value of homogeneous plastic deformation to plastic deformation localized concentration of the transition, which is also the maximum carrying capacity under static stretching conditions.

Principle

In the process of stretching, the material after yielding the stage to strengthen the stage with significantly reduced transverse cross-sectional dimensions of the pull-off exposure to the most vigorous (Fb), divided by the original specimen cross-sectional area (So) obtained stress (σ), called the tensile strength or ultimate strength (σb), in units of N / mm2 (MPa). It represents a metal material to resist damage under tension maximum capacity. The formula is: σ = Fb / So the formula: Fb-specimen pull off the maximum force, N (Newton); So-original specimen cross-sectional area, mm². When the steel yield to a certain extent, due to the internal grain re-arrangement, its ability to resist deformation improved again, although this time the deformation has developed rapidly, it can only be improved with the increase of stress until the stress reaches the maximum value. Then the ability to resist deformation of steel significantly reduced, and large plastic deformation occurs at the weakest point, where the specimen cross section of rapidly shrinking, which appears necking until fracture failure.

Type

In the role of a pure tensile force, without fracture can withstand the maximum load and the ratio of the width of the stretched membrane that, usually N / 5cm to represent. It is divided into the warp and weft tensile strength. Warp: tensile strength stretched along the warp direction; Weft: tensile strength stretching along the weft direction.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595