Tungsten Copper Process

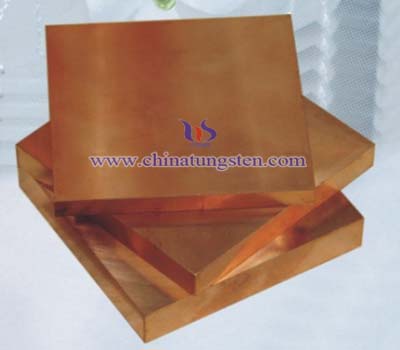

Tungsten copper mechanical has many advantages so that it can be widely used in high-capacity vacuum circuit breakers and microelectronics. And tungsten copper process main includes high-temperature liquid phase sintering, infiltration, activated liquid-phase sintering, mechanical alloying and co-reduction.

High-temperature liquid phase sintering: Tungsten copper high-temperature liquid phase sintering prepares tungsten and copper by mixing and mixing tungsten powder and copper powder in a certain proportion, mixing (adding lubricant at the same time), forming, and sintering and densifying the material at the temperature between the melting point of copper and tungsten.

Powder metallurgy: Powder metallurgy is the process of blending fine powdered materials, pressing them into a desired shape or form, and then heating the compressed material in a controlled atmosphere to bond the material.

Activated liquid-phase sintering: Tungsten copper activated liquid phase sintering can improve the miscibility between tungsten and copper and promote the sintering process by means of adding a small amount of Co, Ni, Fe, Pd and other activated elements.

Mechanical alloying: Tungsten copper mechanical alloying is a kind of sintering method by high-energy ball milling. After mechanical alloying, on the one hand, it can reduce the metal powder granularity, shorten the rearrangement distance by liquid action, improve the powder uniformity, strengthen the densification and improve W-Cu system sintering characteristic.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595