Tungsten Copper Grade>>

Tungsten Copper>>

What is Tungsten Copper>>

Tungsten Copper Properties>>

Tungsten Copper Application>>

Tungsten Copper Machining>>

Tungsten Copper Products>>

Tungsten Copper Rod>>

Tungsten Copper Electrode>>

Tungsten Copper Heat Sink>>

Tungsten Copper Contacts>>

Tungsten Copper Military>>

Tungsten Copper FGM>>

Tungsten Copper AlN>>

Other Copper Alloy Products>>

Customer Service and Support>>

Tungsten Copper Cuw90

90W10Cu Tungsten Copper Properties

1、Content:90W+10Cu2、Density:16.75g/cm3

3、Conductivity:27IACS%

4、Hardness:>260HB

90W10Cu Tungsten Copper Preparation

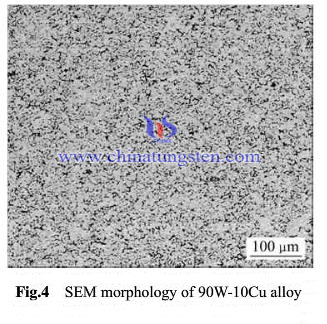

90W10Cu tungsten copper alloy mainly used to suppress the high-speed technology to prepare, and then in 1400 ℃ high temperature hydrogen furnace infiltrated get 90W-10Cu composite. Research repression affect the quality of the pyrometer compacts green density and microstructure of. The results of surface, with the suppression of the temperature rise, the compact density, high-speed suppression obtained at 950 ℃ relative density greater than 80.65% of W skeleton dense tungsten particles connection, distribution, pore connectivity is good. Compacts increases quality, due to the applied energy density is reduced, leading to the green density decreases. By twice the height of repression, the green density further increase; the relative density of 99.5% 90W10Cu materials, thermal conductivity 175W / (mK), tungsten copper alloy 90W10Cu indicators have reached the requirements of the appropriate heat sink material.90W10Cu Tungsten Copper Properties Conclusion

1, At 950 ℃ high speed pressing attainable relative density greater than 80.65% of W skeleton, by infiltration get 90W10Cu composites.2, At room temperature, 600 ℃, 950 ℃ for high-speed tungsten preform pressing, pressing as the temperature rises, the green density increases.

3, High velocity compaction, powder mass increases, due to the ability of additional density decreases, resulting green density decreases. With the increase in the number of high-speed pressing, green density is improved.

4, Using high-speed pressing technology combined with infiltration of 90W-10Cu preparation material and the thermal expansion coefficient and other indicators have reached the requirements of the appropriate heat sink material.

90W10Cu Tungsten Copper Alloy Appication

90W10Cu tungsten copper alloy is mainly used for the production of heat sink material, and due to better performance in all aspects 90W10Cu tungsten copper alloy is also used primarily military.90W10Cu Tungsten Copper Alloy Phase Diagram

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595