Tungsten Copper Wear Resistance Test

Abrasive wear is a form of tungsten copper material wear failure, which is the process of tungsten copper in contact with abrasive materials and metal materials in the relative motion from the substrate to form part of the wear debris. Characterized in that the contact surface of a clear cutting traces. Such as excavator bucket teeth, hammer mill wear failure. Use special abrasive wear tester, first measure the weight of the sample prepared according to standard (g or mg), and replace the card in the chuck, and the chuck to a certain load, the specimen with the abrasive (emery paper) after relative motion, must remove the sample and then measured their stroke weight, known for its weight loss:

W=WFormer-WMill

Tungsten copper material under the same conditions after the abrasion test may be performed relatively. Namely relative wear resistance s=Wear Amount of Reference Sample/Wear Amount of Test Sample

Laboratory Equipment and Samples

2, Emery paper (# 180, # 200).

3, Millionth precision balance.

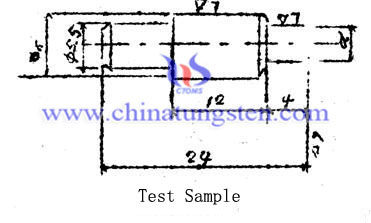

4, Wear-resistant material sample is W70 tungsten copper, its size as shown.

Tungsten Copper Wear Resistance Test Experimental Procedure

2. Measure the original weight of the various samples.

3. Replace the card samples to determine the load and wear test of time, wear tests were conducted.

4. Record the weight of the sample and test after each experimental condition.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595