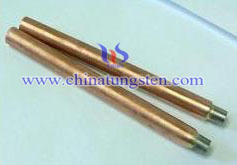

Tungsten Copper Inlaid Electrode

Tungsten copper inlaid electrode usually is used for Cu, Al, Ag and other non-ferrous metals spot welding. But W and Mo do not have good radiating performance actually, we usually use tungsten copper as contact. Tungsten copper through the combination of heat treatment and cold processing methods to ensure performance, it can get the best mechanical properties and physical properties, for EDM electrode has a good vertical, playing sheet does not bend, high-quality advantages, used in high precision and Mirror mold discharge processing, or as a convex welder large molds, fixtures, stainless steel and heat-resistant steel mold or embedded electrode. The other tungsten copper can be used for general purpose resistance welding electrodes, mainly as spot welding or seam welding low carbon steel, coated steel plate electrode, can also be used as electrode welding rod, shaft and cushion material when welding low carbon steel.

In resistance welding process, electrode is an extremely critical consumable parts. The material, shape, shape and size of the working end face, and the cooling conditions of the device have a significant effect on the quality of the welding, the productivity and the consumption of the electrodes. Electrode contact produces high heat and conducted to contact surface of workpiece. Considering the heat conduction in the spot welding, the design of the electrode should take into account the electrode rod and the end, the end and the workpiece contact surface. In addition, extra heat is harmful for fully automatic welding, especially when it at high welding speed.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595