Tungsten Copper Fiber Reinforced Method

Introduction

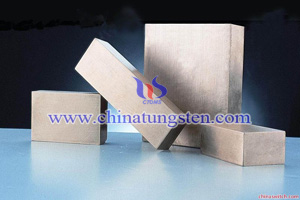

Tungsten copper fiber reinforced method is a kind of process that uses directional tungsten fiber instead of tungsten powder and copper powder overlap each other or cold-rolled short tungsten monofilament fiber and copper powder mixed cold, sintered prepared after the fiber reinforced. It not only has good transverse mechanical properties, but also has excellent conductivity and corrosion resistance.

Type

1. Crystallization strengthening: control crystallization conditions, in the solidification after crystallization to obtain good macrostructure and microstructure, thereby improving the performance of tungsten copper material, and it can be specifically divided into: a. Grain refining: It can provide more grain boundaries for metal structure. Due to the grain boundary hindering the sliding deformation, it can strengthen tungsten copper material on the base of toughness improving; b. Purification enhancement: In the pouring process, the liquid copper fully purified, to minimize inclusions, can significantly improve the performance of tungsten copper material. 2. Deformation strengthening: After plastic deformation by cold working, dislocation movement of the resistance can increase the strength; 3. Solid solution strengthening: By alloying (adding alloying elements) to form a solid solution, tungsten copper material is strengthened; 4. Phase transformation strengthening: By means of heat treatment to change solid phase, which can be divided into: a. Precipitation strengthening (dispersion strengthening): In the metal material can form a stable compound of the alloying elements, under certain conditions, so that the formation of the second phase compounds precipitated from the solid solution, dispersed in the organization, thereby effectively improve the strength of the material, usually precipitation of the alloy the compound is carbide phase; b. Martensite strengthening: After quenching and subsequent tempering of the metal material and heat treatment, the martensite structure can be obtained.

Any feedback or inquiry of Tungsten Copper Alloy Products please feel free to contact us:

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696 ; +86 592 512 9595